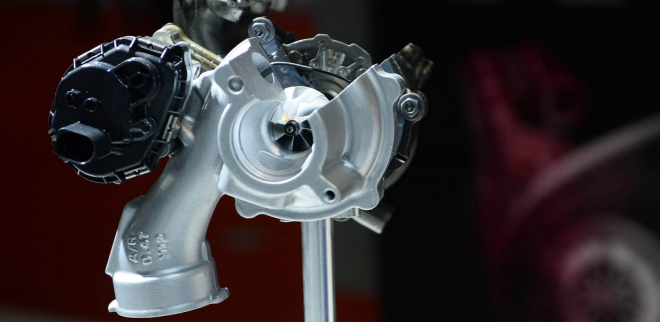

Garrett’s variable nozzle turbine (VNT) technology, which was originally developed for turbocharged diesel applications, has now been redesigned for higher temperature gasoline engines. As a result, the auto industry is turning to this breakthrough technology to help further reduce CO2 emissions by 5 to 10 percent.

Garrett was the first to apply variable geometry turbo technology to mass-production gasoline vehicles through its collaboration with Volkswagen Group and its 1.5L TSI BlueMotion engine launched in 2017.

Designed to work in tandem with Miller cycle combustion, the VNT architecture takes on more work and promotes greater thermal efficiency, resulting in improved fuel economy, reduced CO2 emissions and up to 30 percent faster transient response compared to market-standard wastegate solutions.

Now Garrett is going further. Aerodynamic advances and material innovations in VNT cartridge components are allowing even higher temperature environments – resulting in the award of numerous 950oC and 980oC engine programs (circa 80-90kW/L) and a first launch of this second generation of Gas VNT design in the coming 12 months in advance of the EU7 emission standards. Garrett is also actively developing 1020oC VNT technology for premium vehicles with power ratings up to 100 kW/L, leveraging engineering knowledge won from its global motorsport programs.

Designed to work in tandem with Miller cycle combustion, the VNT architecture takes on more work and promotes greater thermal efficiency, resulting in improved fuel economy, reduced CO2 emissions and up to 30 percent faster transient response compared to market-standard wastegate solutions.

Now Garrett is going further. Aerodynamic advances and material innovations in VNT cartridge components are allowing even higher temperature environments – resulting in the award of numerous 950oC and 980oC engine programs (circa 80-90kW/L) and a first launch of this second generation of Gas VNT design in the coming 12 months in advance of the EU7 emission standards. Garrett is also actively developing 1020oC VNT technology for premium vehicles with power ratings up to 100 kW/L, leveraging engineering knowledge won from its global motorsport programs.

This innovation looks set to herald a seismic shift from wastegate to VNT technology in gasoline powertrains in every corner of the world by 2025, as part of a global sales mix that will also see greater hybridization and growth in electric vehicles.

The most immediate pain point for auto manufacturers is the European 2021 CO2 emission target of 95 grams per kilometer and tougher NOx particulate requirements. This will likely result in reduced volumes of small diesel passenger cars in favor of turbocharged gasoline vehicles.

At the same time, auto makers need to meet growing demand for SUVs which, by their nature, tend to be heavier and exhibit more aerodynamic drag.

To satisfy these competing demands for reduced emissions and greater fuel efficiency without compromising the performance expected by consumers, manufacturers are investing in two principal strategies – electrification and the development of more efficient gas powertrains.